Anhydrous Ammonia

REGULATORY CITATION

OSHA - 29 CFR 1910.111 - Storage and handling of anhydrous ammonia

Origin Date 6-27-1974

WHAT IS IT?

Standards provide requirements for the design, construction, location, installation and operation of anhydrous ammonia systems.

WHO DOES IT APPLY TO?

Employers that store or transfer anhydrous ammonia.

HOW CAN WE HELP?

CLICK HERE to learn how Asmark can help you.

INTRODUCTION

The Occupational Safety and Health Administration (OSHA) sets requirements for the design, construction, location, installation and operation of anhydrous ammonia systems in its Standard on the Storage and Handling of Anhydrous Ammonia in 29 CFR 1910.111. This regulation applies in general industry as well as agricultural settings. The majority of this regulation pertains to design and construction of containers and related equipment. However, there are also sections pertaining to the use of anhydrous ammonia in agricultural settings.

The American National Standard Institute (ANSI) oversees the development of "Requirements for the Storage and Handling of Anhydrous Ammonia," which applies to the design, construction, repair, alteration, location, installation and operation of anhydrous ammonia systems.

STORAGE TANKS

CGA G2.1 - 2014 6.2.2 - Each storage container must be provided with a pressure gauge graduated from 0 psig to 400 psig. Gauges must be designed for use in ammonia service. The gauge must be present, operable and legible.

29 CFR 1910.111(c)(7) - Precaution must be taken against damage to ammonia systems from vehicles. CGA G2.1 - 2014 6.7.1 - Containers and appurtenances must be located or protected by suitable barriers so as to avoid damage by trucks or other vehicles.

Shutoff valves on storage tank openings must be kept closed and protected by suitable means against tampering or theft of product when the installation is unattended. Examples of suitable means could include valve locks, remote surveillance, security systems, fencing, lighting, motion detectors, alarms or chemical additives that render the anhydrous ammonia unusable or undesirable for the illicit use. One means of protection is usually not adequate, and multiple means of protection may be needed.

CGA G2.1 - 2014 5.12 - Aboveground uninsulated containers should have a reflective surface maintained in good condition. White is recommended for painted surfaces, but other colors having similar reflecting characteristics are acceptable. Note: Caution should be exercised to ensure that graphic designs, company logos, etc., do not significantly reduce the necessary reflective characteristics of the container surface.

29 CFR 1910.111(b)(10)(iii) - Stationary storage installations must have an easily accessible shower or a 50-gallon drum of water. CGA G2.1 - 2014 3.4.1.5 - All permanent storage installations must have an easily accessible emergency shower and a plumbed eyewash unit, or at least 150 gallons of clean water in an open top container. Note: It is recommended that the distance from the point of greatest potential exposure to ammonia to the emergency water supply should not exceed ten seconds travel time or 100 feet. Emergency water should be available at each transfer location at the facility and should not have any obstacles or impediments in the way of travel.

29 CFR 1910.111(a)(2) & (b)(2-3) - The requirements regarding data plates for storage tanks of anhydrous ammonia are:

- The ASME manufacturer's data report must be provided when requested by the inspector should repairs, alterations or metallurgical data be required;

- The container must be ASME constructed if installed after November 1, 1987; and,

- The container must be national board registered if installed after November 1, 1987.

- For secondhand and reinstalled storage containers, a manufacturer's data report must be furnished to the inspector if the container is not national board registered. Any post construction repairs and alterations, if made, must meet the requirements of the national board inspection code, and the proper documentation must be available for inspection if requested by the inspector. All container fittings, nozzles and welded seams must be in compliance with the code of construction as judged by the requirements of the national board inspection code.

Ensure all storage tanks used for anhydrous ammonia are equipped with a legible ASME data plate or are currently operated under the provisions of the authority having jurisdiction.

Note: The definition of "authority having jurisdiction" is a person who has the delegated authority to determine, mandate and enforce code requirements by jurisdictional governing bodies. In this case it may be any number of state agencies.

CGA G2.1 - 2014 5.4.3.3 - Tanks without legible data plates must be inspected and tested or be removed from service by the year 2030.

29 CFR 1910.1200(f) - Each container must be marked with "ANHYDROUS AMMONIA" or "CAUTION-AMMONIA" on two sides. Each container must be conspicuously marked with a hazard warning label describing the health and physical hazards of the product, first aid information and an NFPA Diamond. CGA G2.1 - 2014 6.6.1 - Each container or group of containers must be marked on at least two sides, which are visible with the words, "ANHYDROUS AMMONIA" or "CAUTION-AMMONIA," in sharply contrasting colors with letters not less than 3.9 inches high.

29 CFR 1910.111(b)(10)(ii) - Stationary storage installations must have at least two suitable gas masks in readily-accessible locations. Full-face masks with ammonia canisters that have been approved by NIOSH are suitable for emergency action involving most anhydrous ammonia leaks, particularly leaks that occur outdoors. For respiratory protection in concentrated ammonia atmospheres, a self-contained breathing apparatus is required.

CGA G2.1 - 2014 5.9.3 - If containers other than refrigerated containers are to be filled according to the liquid level by any gauging other than a fixed length dip tube gauge, each container should have a thermometer well and thermometer so that the internal liquid temperature can be easily determined and the amount of liquid and vapor in the container corrected to a 60 degrees Fahrenheit basis.

CGA G2.1 - 2014 5.10.8.1 - All stationary storage installations with a water capacity greater than 4,000 gallons must have approved emergency shutoff valves or back-flow check valves installed in the liquid and vapor fixed piping of the transfer system within 5 lineal feet or within reasonable distance of where the hose or swivel piping is attached to the fixed piping. This requirement does not apply to fixed piping feeding a process system. The emergency shutoff valves or backpressure check valves must be protected from any possible pull-away-while-connected incident between the mobile container and the transfer station, such that any break resulting from a pull will occur on the hose or swivel-type piping side of the connection while retaining intact the valves and piping on the plant side of the connection.

Note: Protection from pull-away-while-connected incidents may be accomplished by:

- Reinforced concrete/reinforced concrete and structural steel bulkheads or equivalent anchorage-strong enough not to break and massive enough not to be uprooted by the motor vehicle;

- Use of approved breakaway devices, specifically designed for this purpose; or

- Use of shear fittings designed to conform to good engineering practices.

Protection from pull-away-while-connected incidents is appropriate for all connections to mobile containers. In determining "reasonable distance," protection for persons, property and the environment must be addressed. Such anchorage is not required for tank car unloading.

CGA G2.1-2014 6.4.1-2: The foundation must maintain the lowest point of the tank not less than 18 inches above the ground. If supports of the saddle type are employed, the bearing afforded by the saddles should extend over at least one third (1/3) of the circumference of the shell. Suitable means for preventing corrosion must be provided on that portion of the container in contact with the foundations or saddles.

CGA G2.1-2014 5.11.5 references 85 percent as the volumetric level not to exceed of the container's water capacity, however the installation of mechanical protection (i.e. valves, gauges, etc.) will not protect the tank(s) from being overfilled if multiple tanks are plumbed together with differing 85 percent liquid level lines.

NURSE AND APPLICATOR TANKS

The Department of Transportation (DOT) requires each pressurized vessel transporting a hazardous material in commerce on a public highway to be equipped with a legible ASME data plate. If a nurse tank is missing the data plate or it is illegible, a person may choose any of the following three options:

- Obtain a new replacement ASME data plate from the original manufacturer;

- Perform the required tests and inspections (Visual, Thickness and Pressure) on the nurse tank every 5 years; or

- Remove the tank from service.

Each tank must be marked with a unique owner's identification number. This number must be maintained by the tank owner and the inspector, and be made available to a DOT representative upon request. Each nurse tank must be inspected and tested by a person meeting the requirements of 49 CFR 180.409(d). Prior to marking a nurse tank, the person marking the nurse tank must perform the following tests and inspections:

- External visual inspection and testing using the procedures specified in 49 CFR 180.407(d);

- Thickness tested using the procedures specified in 49 CFR 180.407(i). Nurse tanks with a capacity of less than 1,500 gallons must have a minimum head thickness of 0.203 inch and a minimum shell thickness of 0.239 inch. Nurse tanks with a capacity of 1,500 gallons and above must have a minimum thickness of 0.250 inch. Any nurse tank with a thickness test reading of less than that specified above, on any point on the nurse tank, must be removed from hazardous material service;

- Pressure tested using the procedures specified in 49 CFR 180.407(g). The minimum test pressure is 375 psig. Pneumatic testing is not authorized; and

- After the tanks have successfully passed the external visual inspection and thickness and pressure tests, the tanks must be marked in accordance with 49 CFR 180.415.

CGA G2.1 - 2014 5.12 - Aboveground uninsulated containers for anhydrous ammonia should have a reflective surface maintained in good condition. White is recommended for painted surfaces, but other colors having similar reflecting characteristics are acceptable. Note: Caution should be exercised to ensure that graphic designs, company logos, etc., do not significantly reduce the necessary reflective characteristics of the container surface.

49 CFR 172.326, 172.332, 172.514 & 172.301(a) - Tank markings required for nurse tanks of anhydrous ammonia: DOT 1005 placards (4 sides); "Inhalation Hazard" decal with 2-inch lettering (2 sides); "Anhydrous Ammonia" with 2-inch lettering (4 sides).

CGA G2.1 - 2014 11.5.2 - Each nurse tank must be equipped with the following safety equipment and features:

- For first aid purposes, at least 5 gallons of clean water in a container designed to provide ready access to the water for flushing any area of the body contacted by ammonia;

- A legible decal depicting step-by-step ammonia transfer instructions; and

- A legible decal listing first aid procedures to follow if injured by ammonia.

CGA G2.1 - 2014 5.10.8.1 - All stationary storage installations with a water capacity greater than 4,000 gallons must have approved emergency shutoff valves or back-flow check valves installed in the liquid and vapor fixed piping of the transfer system within 5 lineal feet or within reasonable distance of where the hose or swivel piping is attached to the fixed piping. This requirement does not apply to fixed piping feeding a process system. The emergency shutoff valves or backpressure check valves must be protected from any possible pull-away-while-connected incident between the mobile container and the transfer station such that any break resulting from a pull will occur on the hose or swivel-type piping side of the connection while retaining intact the valves and piping on the plant side of the connection.

Note: Protection from pull-away-while-connected-incidents may be accomplished by:

- Reinforced concrete/reinforced concrete and structural steel bulkheads or equivalent anchorage-strong enough not to break and massive enough not to be uprooted by the motor vehicle;

- Use of approved breakaway devices, specifically designed for this purpose; or

- Use of shear fittings designed to conform to good engineering practices.

Protection from pull-away-while-connected incidents is appropriate for all connections to mobile containers. In determining "reasonable distance," protection for persons, property and the environment must be addressed. Such anchorage is not required for tank car unloading.

Approved emergency shutoff valves must incorporate a reliable actuation system that will close all of the emergency shutoff valves of the piping system on the first attempt in the event of emergency or testing from a remote location.

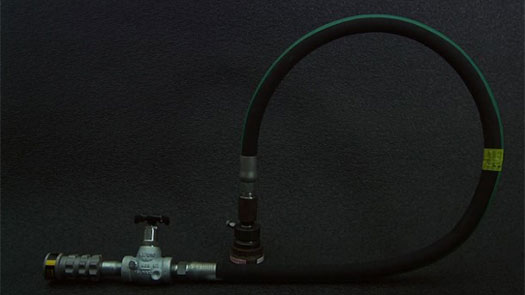

HOSE

29 CFR 1910.111(b)(8) - Hoses used in ammonia service must conform to the joint Agricultural Ammonia Institute-Rubber Manufacturers Association for Anhydrous Ammonia Hose. On all hose one-half inch outside diameter and larger, used for the transfer of anhydrous ammonia liquid or vapor, there must be etched, cast or impressed at 5-foot intervals the following information: Anhydrous Ammonia, XXX psig (working pressure), manufacturer's name or trademark and year of manufacturer. In lieu of the requirement, the same information may be contained in a nameplate permanently attached to the hose.

CGA G2.1 - 2014 5.7 - Dedicated hoses should be used for ammonia transfer service only and should not be used in other services. Hose subject to container pressure must be designed for a minimum working pressure of 350 psig and a minimum burst pressure of 1750 psig. Hoses must be replaced if frayed or damaged. Hoses must be immediately removed from service when failing inspection or requalification testing, or when they have reached their maximum service period. Possible hose assembly weaknesses:

- Cuts or nicks. Hose found with cuts or nicks in the hose structure that damage the reinforcement material must be immediately removed from service. Small cuts or nicks in the outer cover that do not penetrate to the braiding must not be cause for hose rejection unless the cover in the immediate area is loose or the reinforcement material is cut or exposed.

- Deterioration. Hoses found with damage to the reinforcement material by excessive abrasion, weathering, corrosion or other means, or damage to the outer cover causing exposure of the reinforcement braid, must be immediately removed from service.

- Blistering. Hoses found with evidence of blistering or loose outer cover must be immediately removed from service and evaluated to determine the cause and if the hose is suitable for continued service. Once the cover is pulled loose from the hose braid, a pocket develops that could accumulate water and be a possible site for corrosion or rusting. Note: Pricking the hose cover is necessary for satisfactory hose performance. A uniformly pricked cover should not be viewed with alarm.

- Bulges, flat spots or kinks. Hoses found with evidence of bulges, flat spots or kinks must be immediately removed from service.

- Coupling damage or slippage. Hoses found with evidence of coupling slippage, or the appearance of cracks, severe dents or excessive corrosion involving couplings or crimped connections, must be immediately removed from service. Hoses found with apparent damage to or excessive wear of the threaded or connecting surfaces of a hose coupling, must also be immediately removed from service and evaluated to determine (by use of a gauge or template) if the hose is suitable for continued service.

- Markings. When all markings placed originally on a hose by the manufacturer to identify maximum rated working pressure and other specifications have been obliterated, the hose must be immediately removed from service. For hoses with markings affixed to the outer hose ends, when the maximum rated working pressure and other specifications have been obliterated, the information must be immediately reaffixed or the hose must be immediately removed from service.

- Leaks. Any hose found with leaks must be immediately removed from service.

- Maximum service period. Although found free of any observable conditions, hoses must be permanently removed from service that have been installed and used over a period of time which exceeds the shorter service life of either:

- The service life recommended by the manufacturer of the hose; or

- If used in conjunction with the additive, the service life of the ammonia hose as recommended by the manufacturer of the additive.

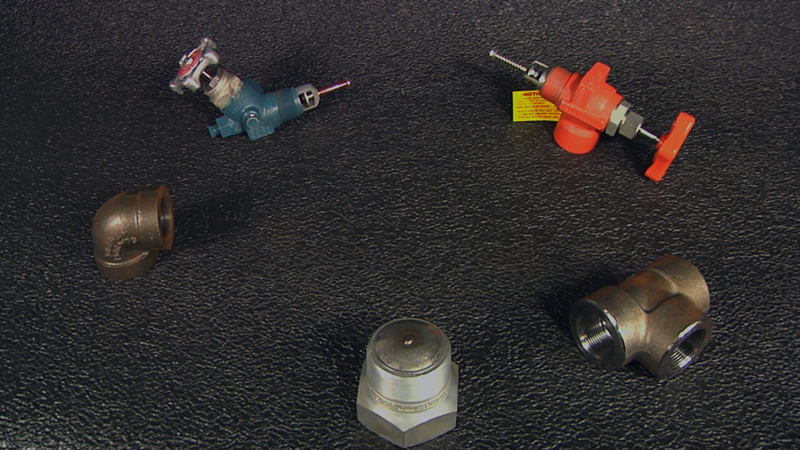

VALVES

29 CFR 1910.111(b)(6)(vi) - Excess flow and back pressure check valves must be located inside of the container or at a point outside as close as practicable to where the line enters the container. Valves installed outside must include metal flex hose to prevent any undue strain between the container and the valve.

CGA G2.1 - 2014 5.5.11 - Each filling connection on non-refrigerated container openings must have a positive shutoff valve in conjunction with either an approved internal back-pressure check valve or an approved internal excess flow valve as appropriate. Vapor connections on non-refrigerated containers must have a positive shutoff valve together with an approved internal excess flow valve. Quick opening (1/4 turn) valves are not recommended for use on transfer lines.

29 CFR 1910.111(b)(6)(iii) - Excess flow valves must close automatically at the rated flows of vapor or liquid as specified by the manufacturer. The connections and line, including valves and fittings being protected by an excess flow valve, must have a greater capacity than the rated flow of the excess flow valve so that the valve will close in case of failure of the line or fittings.

CGA G2.1 - 2014 11.2.5 - All vapor and liquid connections, except pressure relief valves and those specifically exempt, must be equipped with approved excess flow valves or may be fitted with quick-closing internal valves, which must remain closed except during operating periods.

29 CFR 1910.111(b)(9)(ix) - A hydrostatic relief valve must be installed between each pair of valves in the liquid ammonia piping or hose where liquid may be trapped, so as to relieve into the atmosphere at a safe location.

29 CFR 1910.111(b)(9) - Containers for anhydrous ammonia must be provided with one or more safety relief valves of the spring-loaded or equivalent type. The discharge from safety-relief valves must be vented away from the container upward and unobstructed to the atmosphere. All relief-valve discharge openings must have suitable rain caps that will allow free discharge of the vapor and prevent entrance of water.

CGA G2.1 - 2014 10.3 - Containers must be provided with pressure relief devices as required by DOT regulations. A cylinder containing less than 165 pounds of ammonia is not required to have a pressure relief device. Pressure relief device equipment used on DOT containers must be inspected, repaired or replaced according to DOT regulations.

Offered as guidance, all non-refrigerated system openings and appurtenances (tank ports, truck, rail, nurse tank riser loading and unloading areas), except for pressure relief valves, pressure indicating devices, thermometer wells, liquid level indicators or hosing should be marked, stenciled, tagged or decaled to indicate whether the opening is in contact with the liquid or vapor phase.

If paint is used to identify the phases, the colors must be contrasting, differentiating liquid from vapor. The valves and lines must be painted to within three feet, except for hosing, of the system openings. Note: Some states such as Minnesota specify liquid must be orange and vapor yellow as an example. Refer to your state for any state-specific requirements.

PIPING, TUBING AND FITTINGS

CGA G2.1 - 2014 5.6 - All piping, tubing and fittings must be made of steel or other materials suitable for anhydrous ammonia service. Brass, copper or galvanized steel pipe or tubing must not be used. All piping must be supported in accordance with good piping practices, and provisions must be made as necessary for expansion, contraction, impact, vibration and settling.

Piping used on non-refrigerated systems must be at least ASTM A53 Grade B seamless or electric resistance welded pipe. Pipe joints must be threaded, welded or flanged. Pipe must be at least Schedule 40 when joints are welded or welded and flanged. Pipe must be at least Schedule 80 when joints are threaded. Threaded nipples must be seamless. Cast iron fittings must not be used.

After assembly, all piping, fittings and tubing must be tested and proved to be free from leaks at a pressure specified by ASME B31.3 or ASME B31.5 as appropriate. Underground piping must be evaluated at a minimum of every 5 years to ensure leak tightness.

PERSONAL PROTECTIVE EQUIPMENT

29 CFR 1910.132(a) - Personal Protective Equipment (PPE) must be provided, used and maintained wherever it is necessary by reason of hazards of process, environment or chemical hazards.

CGA G2.1 - 2014 3.4 - All permanent storage installations must have on hand, at a minimum, the following equipment for personal protection:

- One pair of protective gloves impervious to ammonia for each employee, plus at least one spare pair;

- One pair of protective boots impervious to ammonia for each employee.

- One protective slicker and/or protective pants and jacket, all impervious to ammonia.

- Chemical splash goggles or chemical splash goggles worn with a full face shield for each employee, plus at least one spare pair. A full face shield, if used, must only be worn as secondary eye protection, supplementing the primary eye protection afforded by the chemical splash goggles. A face shield is not to be worn as a substitute for a proper primary eye protection device such as goggles.

TRAINING

29 CFR 1910.111(b)(13)(ii) - The employer must ensure that unloading operations are performed by reliable persons properly instructed and given the authority to monitor careful compliance with all applicable procedures.

CGA G2.1 - 2014 3.1 - Any person required to handle, transfer, transport or otherwise work with ammonia must be trained to understand the properties of ammonia, to become competent in safe operating practices and to take appropriate actions in the event of a leak or an emergency. Refresher training should be completed at least every three years.

CGA G2.1 - 2014 5.10.2 - At least one qualified operator experienced in the procedures must monitor the transfer of ammonia from the time the connections are first made until they are finally disconnected. Such monitoring may be performed by a person on site, or from a remote location or by electronic means. Capability must be provided to halt the transfer in the event of an emergency.

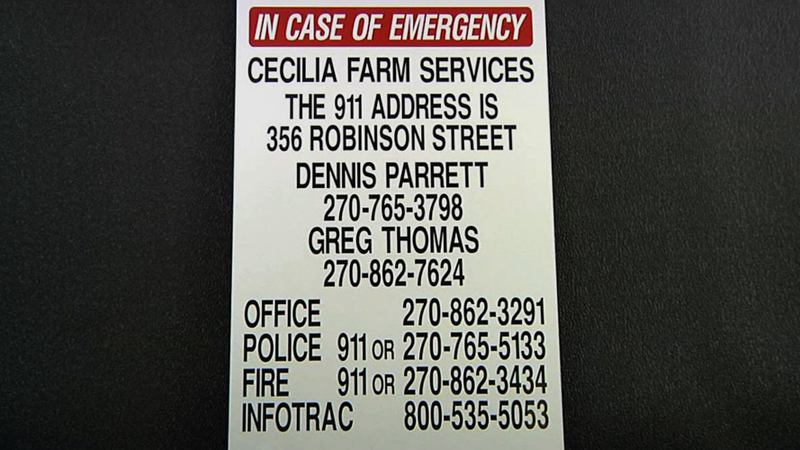

EMERGENCY NOTIFICATION SIGN

CGA G2.1 - 2014 6.8 - A legible sign must be displayed on the premises at which a storage system is located, so as to be readily visible to emergency response personnel with lettering not less than 2-inches in height, stating the following:

- The phrase "EMERGENCY INFORMATION";

- The name of the facility;

- The name and title of at least two responsible persons;

- The area code and telephone number(s) of each person listed; and

- The phrase, "the 911 address is," and the appropriate 911 address.

FAQs AND INTERPRETATIONS

STANDARD

INTERPRETATIONS

COMPRESSED GAS

ASSOCIATION

HOW CAN WE HELP?

LEARN MORE ABOUT WHAT

ASMARK CAN DO FOR YOU