Guarding, Shaft and Gear Machinery

REGULATORY CITATION

OSHA - 29 CFR 1910.219 - Machine guarding

Origin Date 6-27-1974

WHAT IS IT?

Standard protects employees by requiring machine guards.

WHO DOES IT APPLY TO?

Employers with employees who use machines where any machine part, function, or process may cause injury.

HOW CAN WE HELP?

CLICK HERE to learn how Asmark can help you.

OVERVIEW

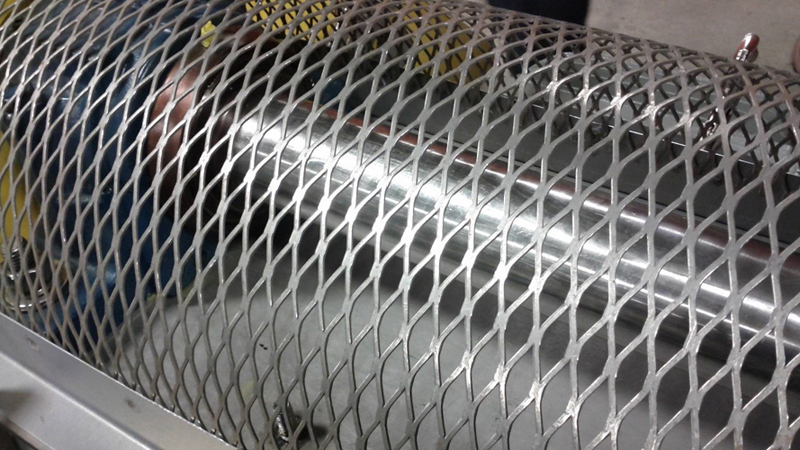

Employees can be protected from workplace hazards and potential machinery-related injuries caused by moving machine parts when employers properly require the use of machine guards. All exposed parts of horizontal, vertical and inclined shafting, 7 feet or less from the floor or working platform, excepting runways used exclusively for oiling or running adjustments, must be protected by a stationary casing enclosing the shafting completely or by a trough enclosing the sides and top or sides and bottom of the shafting as the location requires.

Standard guards must be secured by the use of expanded metal, perforated or solid sheet metal, wire mesh on a frame of angle iron, or iron pipe securely fastened to the floor or to the frame of the machine. All metal should be free from burrs and sharp edges. Expanded metal, sheet or perforated metal and wire mesh must be securely fastened to frame.

The materials and dimensions specified in this paragraph apply to all guards, except horizontal overhead belts, rope, cable or chain guards more than 7 feet above floor or platform. All guards must be rigidly braced every 3 feet or fractional part of their height to some fixed part of machinery or building structure. Where a guard is exposed to contact with moving equipment additional strength may be necessary. Wood guards may be used in certain industries where conditions would cause the rapid deterioration of metal guards. In all other industries, wood guards must not be used.

Guards for horizontal overhead belts must run the entire length of the belt and follow the line of the pulley to the ceiling or be carried to the nearest wall, enclosing the belt effectively. Where it is impracticable to carry the guard to wall or ceiling, construction of a guard must enclose completely the top and bottom runs of belt and the face of pulleys. Suitable reinforcement must be provided for the ceiling rafters or overhead floor beams to sustain the weight and stress likely to be imposed by the guard safely.

The interior surface of all guards must be smooth and free from all projections of any character, except where construction demands it. Protruding shallow roundhead rivets may be used. Overhead belt guards must be at least 1/4 wider than belt which they protect. Projecting shaft ends must present a smooth edge and end and must not project more than one-half the diameter of the shaft unless guarded by nonrotating caps or safety sleeves.

FAQs AND INTERPRETATIONS

OSHA MACHINE

GUARDING E-TOOL

OSHA STANDARD

INTERPRETATIONS

HOW CAN WE HELP?

LEARN MORE ABOUT WHAT

ASMARK CAN DO FOR YOU